About Davies Molding

Davies Molding is the preferred choice for all your molding needs, offering a legacy of excellence since 1933. For over 90 years we have been committed to quality, innovation, and outstanding customer satisfaction. Our achievements in the molding industry speak for themselves through our longstanding relationships with a majority of the Fortune 500 companies. These trusted partnerships demonstrate our ability to consistently deliver large quantities of durable, high-quality parts that stand the test of time.

In 1987, Davies Molding joined the Heico collection of companies, a billion dollar multinational organization. In the fall of 1991, Davies Molding moved to a suburb of Chicago, Carol Stream, Illinois where it is located today in 99,000 square foot facility. Davies has a history of consistently providing quality molded products.

We are dedicated to using the highest quality and widest variety of materials to ensure each project is a perfect fit and provides the highest quality solution.

With over 90 years of molding expertise, the capacity and technology, Davies is your perfect partner to bring your custom molding projects to life with unmatched reliability and precision.

Choose Your Path with Davies Molding

Davies Molding History

Davies Molding From the Beginning

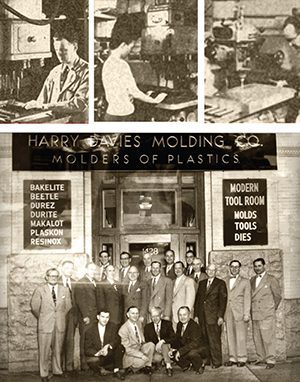

In 1933, Davies Molding as we know it today had its beginnings with only seven molding presses and three punch presses. Located in downtown Chicago, Davies Molding was then known as, and is still regarded today by some, as "The Harry Davies Molding Company" after owner Harry Davies. The small, single-room company was started during a time when the economy was depressed and work was scarce. Yet with hard work and determination, Davies Molding soon established strong roots as a quality plastics molder. Known as a phenolic molder, Davies manufactured numerous parts including knobs, handles, cases, daka-ware ashtrays, as well as custom molded products. During the 1940’s as WWII escalated, Davies Molding became a supplier of plastic components for the war effort. Also, in the 1940s, Davies introduced the brand name Daka-ware to our revolutionary product line using a synthetic material called Bakelite. In 1954, Harry Davies retired and, in turn, sold his interest in the company to a handful of people including his nephew, Ted Davies.

A second, smaller plant was established in 1966 to accommodate the demand for plastic component parts. One year later, the original plant was destroyed by a fire which forced the smaller plant to operate 7 days a week, 24 hours a day. To off-load the burden of this small plant, Davies moved to a facility on the west side of Chicago later that year. For 25 years this location served Davies well; however, as the economy flourished and as Davies acquired new injection molding presses, Davies needed to expand once again.

Davies Molding Moving Forward

In 1987, Davies Molding joined the Heico collection of companies, a billion dollar multinational organization.

In the fall of 1991, Davies Molding moved to a suburb of Chicago, Carol Stream, Illinois where it is located today in a 99,000 square foot facility. The facility houses forty-five (45) thermoset compression molding machines, eight (8) thermoset injection molding machines and thirty-two (32) thermoplastic injection molding machines, all ranging in tonnage from 40 to 500 tons.

The once small plastic molding company that stood in downtown Chicago is now the largest manufacturer of plastic knobs and handles in the world today. A Davies’ knob or handle can be found on countless products including industrial machinery, lighting equipment, lawn & garden equipment, power tools, cookware, barbecue grills, food processing equipment, medical & lab equipment, electronic equipment, fitness & recreational equipment, and more. Although Davies Molding is well known for its standard knobs, handles and cases, did you know we also have extensive custom molding capabilities? We have molded parts for a majority of the fortune 500 companies with a wide range of industries including the oil and gas industry, as well as automotive, food service equipment, HVAC, lighting, and electrical and more. With our extensive experience in the design-to-product process, we are uniquely positioned to provide unmatched support for projects of any scale.

Discover the Craftsmanship Behind Our Molding Manufacturing Process

Discover the world of Davies Molding with two simple choices. Dive into our product catalog to find what you need or take the first step towards turning your unique project into reality. Whether it's off-the-shelf solutions or a custom masterpiece, the power is in your hands.