Engineering Specifications: Rotary Injection Molding

Exploring Efficiency and Precision with Rotary Injection Molding

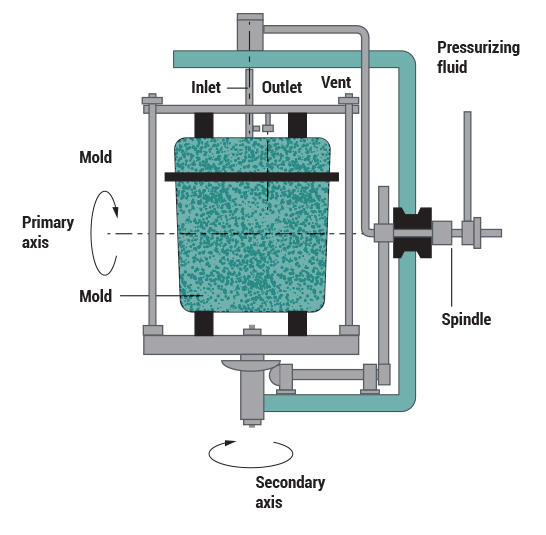

A plastic shaping process in which resin heats inside a rotating mold and forms hollow, one-piece plastic products. This type of method is suitable for small and complex shapes.

Rotary injection molding represents a sophisticated manufacturing technique that involves a rotating carousel of molds. This carousel moves in a controlled manner, allowing each mold to undergo different phases, including plastic injection, precise cooling, and the ejection of completed components.

The advantages of rotary injection molding includes the following:

- It enables concurrent operation with multiple molds, significantly boosting production efficiency.

- Secondly, it excels in making intricate parts, thanks to its precise pressure and careful processes.

- It is resource efficient as it minimizes material waste through precise control over the molding process.

If you looking for intricate plastic component production and process optimization, rotary injection molding offers a strategically advanced solution.

Have any questions about materials and capabilities?

Contact Us through our online form or call 1-800-554-9208.