Custom Molding and Contract Molding Expertise: Unlock Your Vision

We are leaders in contract molding, specializing in the custom molding of thermoset and thermoplastic injection, transfer, and compression parts.

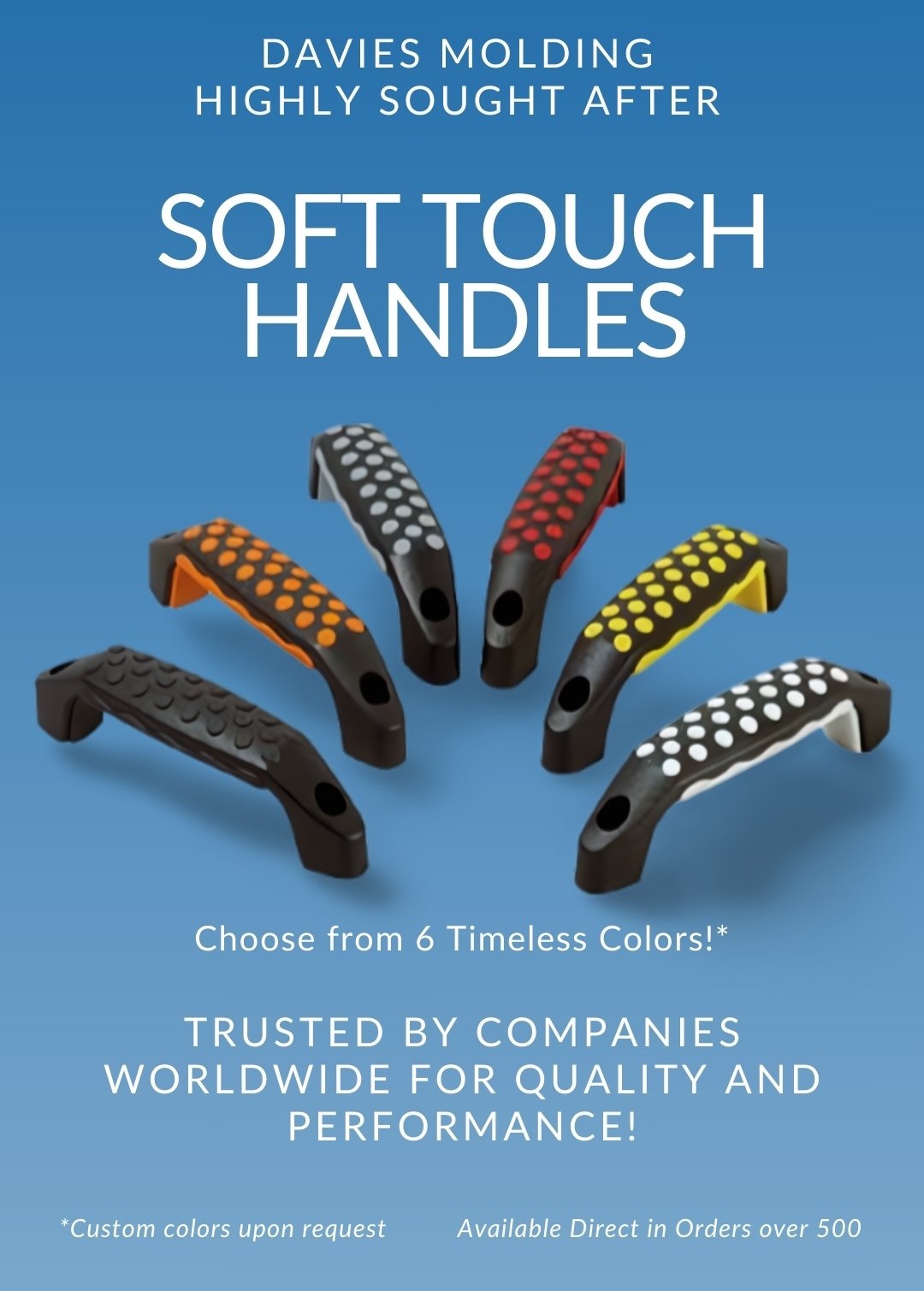

Davies Molding, a women-owned leader in custom molding, backed by a multi-billion-dollar organization, specializes in scalable thermoset and thermoplastic molding solutions. We have built this business on a commitment to excellence regardless of project size or requirements. This excellence in injection molding and compression molding has set us apart for over 90 years.

As a premier composite and plastic molding company we offer the choice of size, shape, and material. Each part is crafted with strict control measures to ensure quality, reliability and durability which has made us the go-to custom molder for a wide variety of industries including power, infrastructure, automotive, electronics, aerospace, and medical. We have honed our molding process over the years allowing cost savings without compromising on quality, ensuring projects are completed within budget.

Contact Davies today and discover the benefits of partnering with the industry leader in custom compression molding.

Why Choose Davies Molding for Custom Molding?

Industry Leaders Trust Davies: Serving Fortune 500 Companies Across a Wide Range of Industries for Over 90 Years!

Aerospace

Agricultural

BioTechnology

Climate Control

Construction

Defense

Electronics

Food Equipment

Government

Medical

Music Industry

Petroleum

Power Equipment

Transportation

Utilities

Unleashing Innovation in Custom Thermoset and Thermoplastic Molding Solutions

Davies specializes in delivering unparalleled expertise and innovation in custom thermoplastic and thermoset molding solutions. When you choose to partner with us, you gain access to a range of benefits tailored specifically to your needs:

Unrivaled Expertise

We have extensive knowledge and expertise in thermoset and thermoplastic molding, guaranteeing top-quality results for your unique projects. View our custom molding portfolio.

Comprehensive Support

Our team of experts will help you from start to finish, providing support at every step of the way.

Precision and Quality

We prioritize precision and quality in every project. Leveraging cutting-edge technology and techniques, we deliver flawlessly molded parts that meet the most stringent molding industry standards.

Extensive Material Options

We offer various options for your custom plastic molding project. Whether you require thermoset material or thermoplastics, we can meet your specific needs.

Tailored Solutions

We collaborate with you to develop a personalized solution that aligns with your vision. This ensures that the solution functions effectively, has a long lifespan, and has an appealing appearance.

Swift Turnaround

Time is of the essence, and we prioritize efficiency without compromising quality. Our streamlined processes and efficient production capabilities allow for fast turnaround times without sacrificing excellence.

Unleashing Manufacturing Excellence: Davies Molding's Expansive Facilites and Limitless Capabilities

Davies Molding boasts an impressive facilities spanning a total of 132,000 square feet with machines ranging from 60 to 500 tons. We are setup to accommodate a vast range of thermoset and thermoplastic manufacturing projects. Whether a project requires injection, compression, and transfer molding, we achieve outstanding results, even for the most intricate custom molding projects.

Our state-of-the-art facility is equipped with cutting-edge machinery, advanced technology, and a highly skilled workforce. We have the molding expertise for a wide range of custom projects, plus every project will be completed with the highest standards of quality and precision. Plus, our team will support you whether you are in the beginning stages of design and prototyping or at the production and assembly stage.

Trust Davies Molding to make your custom molding vision a reality, with the skills and resources to meet your needs.

Choose From a Wide Range of Molding Materials

Unleashing Possibilities with Davies Custom Molding

At Davies, we offer a wide range of materials options to choose from. We offer materials for both injection and compression molded parts. We source the finest materials in the industry so that we can deliver exceptional quality and performance. The key highlights of the materials we utilize are:

- Thermosetting Materials: With a wide array of thermosetting options, we can create parts that exhibit excellent dimensional stability, heat resistance, and electrical insulation properties. Our thermosetting materials include phenolics, melamines, epoxies, and more.

- Thermoplastics: Davies Molding leverages a variety of thermoplastic materials to cater to different project requirements. Our thermoplastic options include ABS, polycarbonate, polypropylene, nylon, and other high-performance polymers.

- Versatility: We offer a large selection of materials for both Thermoset and Thermoplastic projects.

- Custom: We understand the importance of tailored solutions and can customize materials for color, texture, flexibility, or rigidity, providing endless possibilities for customization.

- Quality Assurance: All materials used in our manufacturing processes undergo rigorous testing and inspection to ensure they meet our stringent quality standards and regulatory compliance.

Acetal

Acrylics

Acrylonitrile-butadiene Styrene (Abs)

Alkyds

BMC (Bulk Molding Compound)

Diallyl Phthalate (Dap)

Epoxy

Melamine-formaldehyde

Nylon

Phenolic

Polyamide-imide

Polyarylates

Polybutylene

Polycarbonate

Polyethylene

Polyimides

Polyketones

Polyphenylene Oxide, Modified

Polyphenylene Sulfide

Polypropylene

Polystyrene

SMC (Sheet Molding Compound)

Styrene Acrylonitrile

Sulfone Polymers

Thermoplastic Polyester (Saturated)

Thermoset Polyester

Urea-formaldehyde

Custom Molding Solutions Tailored to Your Needs: Explore Davies Molding's Secondary Options for Perfectly Crafted Solutions

3D CAD Imaging

Assembly

Bagging

Branding

Buff and Polish

Chrome Plating

Custom Color Matching

Decorative Inlays

Decorative Pointers

Drilling

Hot Stamping

Kitting

Lapping

Laser Engraving

Machining

Packaging

Pad Printing

Paint Coatings

Paint Fill

Reaming

Sand Blasting

Silk Screen

Tapping

Turning

Ultrasonic Welding

Vacuum Metalizing