Home Office

Carol Stream, IL

350 Kehoe Blvd,

Carol Stream, IL 60188

630 510 8188

In the fall of 1991, Davies Molding moved to a suburb of Chicago, Carol Stream, Illinois where it is located today in a 99,000 square foot facility. The facility houses forty-five (45) thermoset compression molding machines, eight (8) thermoset injection molding machines and thirty-two (32) thermoplastic injection molding machines, all ranging in tonnage from 40 to 500 tons. We specialize in insert compression molding and insert injection molding.

Additionally, in 2022, Davies molding expanded operations by adding an additional 15 injection molding presses with both thermoset and thermoplastic capabilities. This increased capacity not only enables the expansion of our injection molding services, but also facilitates the support of out international growth initiatives.

Also on premises are secondary or finishing machines, which are capable of drilling, tapping, set screw assembly, pad printing, hot stamping, branding, engraving, bagging, and sand blasting.

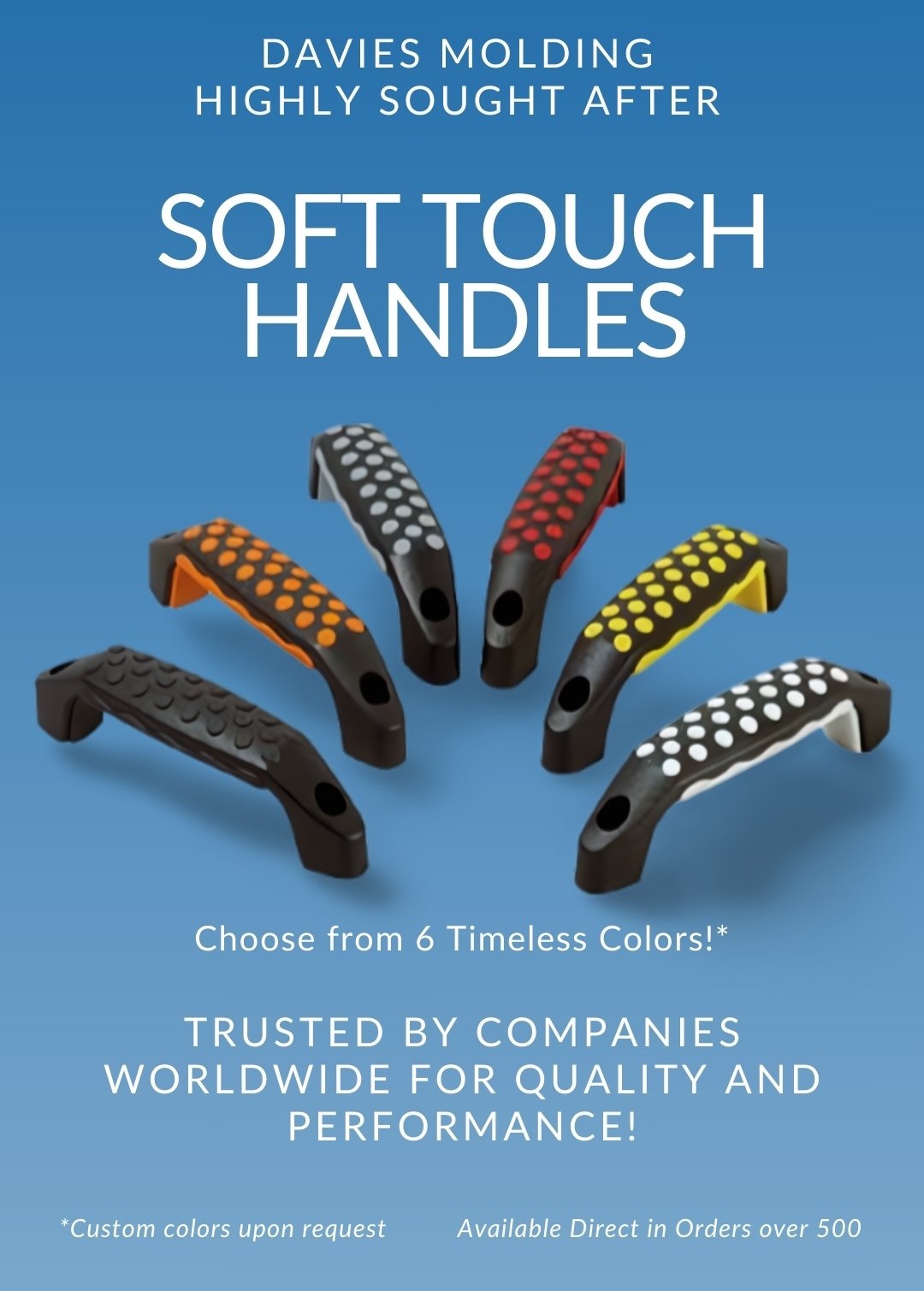

The once small plastic molding company founded in 1933, that stood in downtown Chicago, is now the largest manufacturer of plastic knobs and handles in the world today. A Davies’ knob or handle can be found on countless products including industrial machinery, lighting equipment, lawn & garden equipment, power tools, cookware, barbecue grills, food processing equipment, medical & lab equipment, electronic equipment, fitness & recreational equipment, and more.

Although Davies Molding is well known for its standard knobs, handles and cases, did you know we also have extensive custom molding capabilities? We parts for the largest companies in the world including molding butterfly seat valves and frac balls for the oil and gas industry, as well as molding automotive, food service equipment, HVAC, lighting, and electrical custom plastic parts.